Can you introduce yourself?

After some rich years leading some projects for French car manufacturers and suppliers, I decided to move from a user to a creator of driving simulators. From 2009, I supervised international projects for OKTAL (former name of the AVSimulation office). When AVSimulation was created in 2017, the need for “off-the-shelf” simulators was clear and I moved to a new position as Product Manager. My job is to define the road map of the simulator products and keep as close as possible to our users and clients.

Christian Schost

Can you explain in a few words what a motion system is and what it brings to a driving simulator?

There is a growing demand for driving simulators capable of achieving high levels of fidelity, to be driven by candid or expert drivers.

The activity of driving a vehicle is a combination of parallel tasks. When the driver acts on the controls (like the steering wheel or the pedals), they get feedback on different senses. This feedback can be visual or auditory, and common solutions exist to feed these cues to the driver. But vestibular and kinesthetic cues are also expected by the driver to evaluate the intensity of the braking or the cornering speed.

The human body expects acceleration and rotational speeds for this high level of immersion. The motion system is one or several actuation solutions which are controlled by the simulation software and which will move the driver to provide these cues.

This feedbacks is critical as the driver is involved in closed loops between the actions on the vehicle and its reactions.

But not every simulator requires the most advanced and complex rendering systems. For example, AVSimulation also supplies static simulators. These simulators are less complex, but require an adaptation of the driver who will look for the information feedback in other channels, predominantly in vision.

The quality of the rendering of this feedback needs to be adapted to the use case of the simulator and to the expected realism level of the driver behavior. The value of the observed actions of the driver relies on the accuracy of the feedback. Like everywhere, the design of a simulator aims at a right balance, best fit and compromise between the cost and the use cases.

When the focus of an experiment strongly involves the dynamics model of the vehicle, or even the way the driver positions the vehicle on the road lanes within the traffic, it becomes critical to provide fast and accurate kinesthetic feedback. Moreover, a lack of homogeneity in the quality of the cues can induce discomfort for non-expert drivers.

A motion system has two main functions: providing a coherent level of cues to the users, and feeding the driver with the sufficient quality of inputs for the expected level of realism.

We can consider that there are several scales of motion systems on driving simulators:

- The ones providing the minimum level of restitution for realistic actions on the controls and comfort (usually 3 DoF systems),

- High realism: these motion systems aim at providing up to scale 1 accelerations and rotations to the users. As a consequence they will reach higher speeds and have larger motion envelopes,

- Sometimes, the target is not to get a homogenous level of rendering on all dimensions, but to focus on a few degrees of freedom and the highest level of accuracy. Applications like high dynamics and NVH require higher power in the actuation devices to try to provide the minimum achievable latency, but they offer shorter durations of the accelerations (then shorter excursions).

The number of DoF is frequently mentioned when talking about motion systems. What is it exactly ?

In our 3D world, there are only 6 possible moves: the translations on the three axes and the rotations around the same ones. A car evolving on a road uses all of these degrees of freedom.

Driving simulators are usually designed for an homogeneous level of restitution, then the most versatile systems come with the same 6 degrees of freedom. But more compact simulators can be constrained by the available room or by the purchasing cost and will focus on the most critical DoF.

Compact simulators like SimEASY+ focus on pitch, roll and elevation (3 DoF). They are not capable of rendering longitudinal or lateral accelerations, but they are quick and inform the driver with the beginning of the reactions of the vehicle body.

SimEASY+

The standard Stewart platforms are capable of rendering the 6 degrees of freedom. They can have long actuators, making it possible to use the tilt coordination algorithm to use gravity and simulate long lasting accelerations. These systems exist as off-the-shelf products, and have a limit: the same six actuators are all used to render all the moves. This means that it is not possible to get the same maximum performances on two or more axes at the same time. Driving simulators use of course rotation around the vertical axis (yaw) as the driver follows a curved road. The yaw rotation might use the full stroke of the actuators to keep a realistic factor, but in that case the motion system has less or no available stroke to render translation or other rotations.

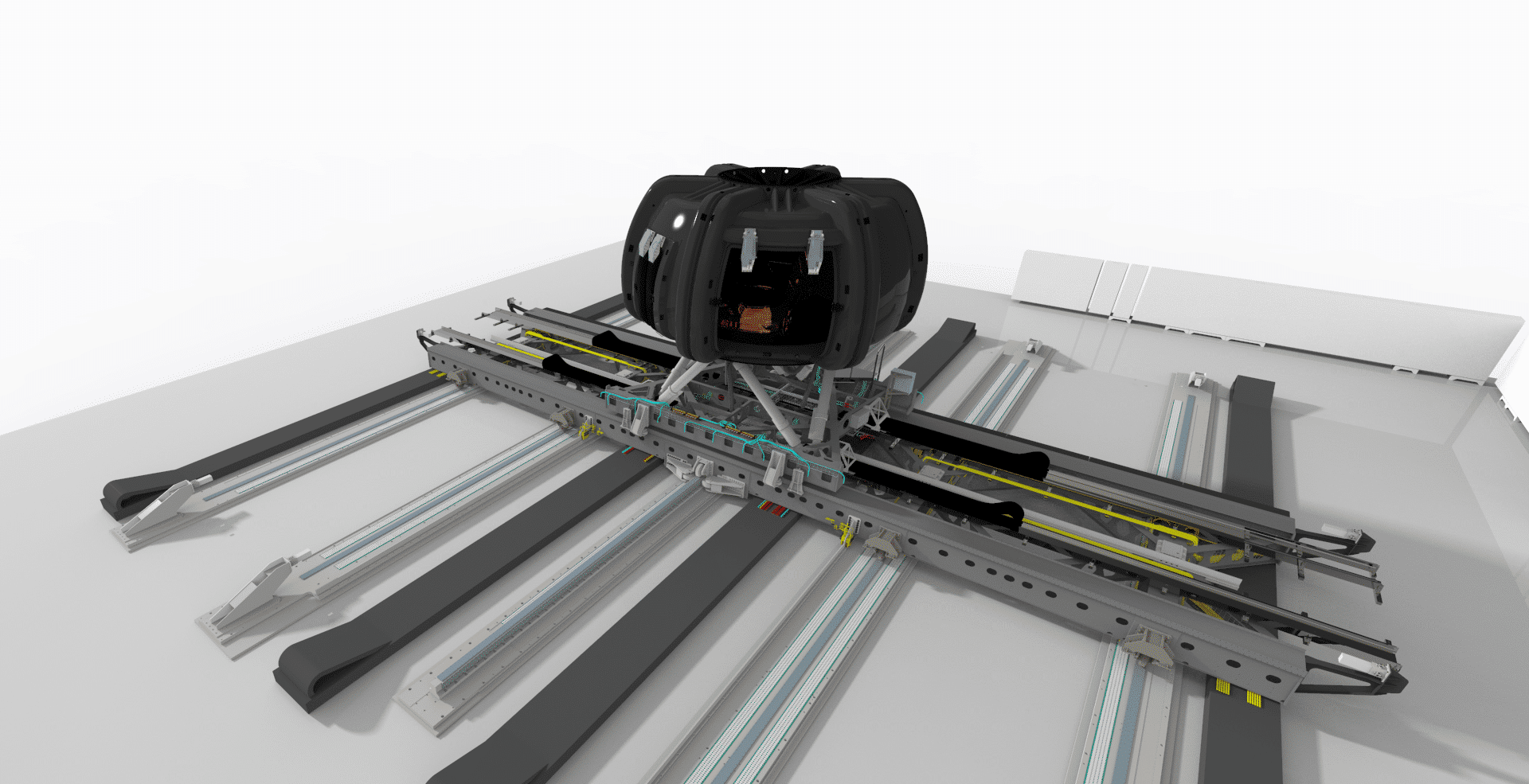

This is why some simulators come with parallel motion systems in parallel. For example the SimELITE simulators have more degrees of freedom (9), because they have motion systems under and above the Stewart platform. The advantage of such systems is that the multi-axis motion systems can focus on less axes and optimize their usable stroke on these. Another benefit of parallel systems is that they can cover the same axes with different performances: a large X-Y platform can be moving the whole simulator, and a vibration system can be added close to the driver to cover a larger range of frequencies.

So the number of DoF is a good indicator of the capabilities of a motion system, but what are the other aspects to consider?

The motion systems can render cues on up to 6 degrees of freedom, and have their own capabilities. The number of actuated DoF is an indication of the possibilities, , but it is crucial to understand that there are other factors to ensure the best fit between the motion system and the expected use cases of the simulator:

- The maximum values of the accelerations. If they are too small, it will be difficult to render and differentiate the standard and unusual maneuvers,

- The duration of the same accelerations, which is limited by the maximum velocity of the simulator et les excursions possibles des systèmes de mise en mouvement,

- The effective latency,

- The smoothness,

- The noise level,

- The range of frequencies which can be rendered …

All of these (and others) come into a large equation to define the best architecture of the motion system.

The main aspect is to ensure that the design of the simulator fits the requirements for a known level of fidelity and for identified use cases.

I’ve heard about motion cueing. Can you explain in a few words what it is?

The dynamics model in SCANeR computes the reaction of the simulated vehicle on the ground at 1000 Hz (or more). It provides the exact values of the dynamics for the simulated vehicle.

On the other end, an advanced driving simulator can use several motion or actuation systems in parallel. And each motion system is usually capable of rendering cues on several axes, and has its own physical performances and limitations.

The cueing algorithm is a combination of filters and transfer functions which transform the outputs of the dynamics model into orders for the different motion systems of the same simulator. It will split the inputs in terms of frequencies, and integrate the tilt coordination technique. This algorithm is fundamental, it ensures that the simulator makes a full profit of the capabilities of its own mechanical systems.

If you enjoyed this interview and want to know more about motion system, you can read this article.